Crimping Insights

A professional crimping job decides whether you and the crew celebrate an incredible catch or partake in a long, depressing ride back to the dock — and we’ve all been on both sides of that coin. As basic as crimping seems, the “art” is anything but elementary. Selecting the correct sleeve and material, sizing it to the leader and properly executing the connection are crucial. To keep you and your next big fish from parting ways unexpectedly, heed the insights that follow.

SIZED TO PERFECTION

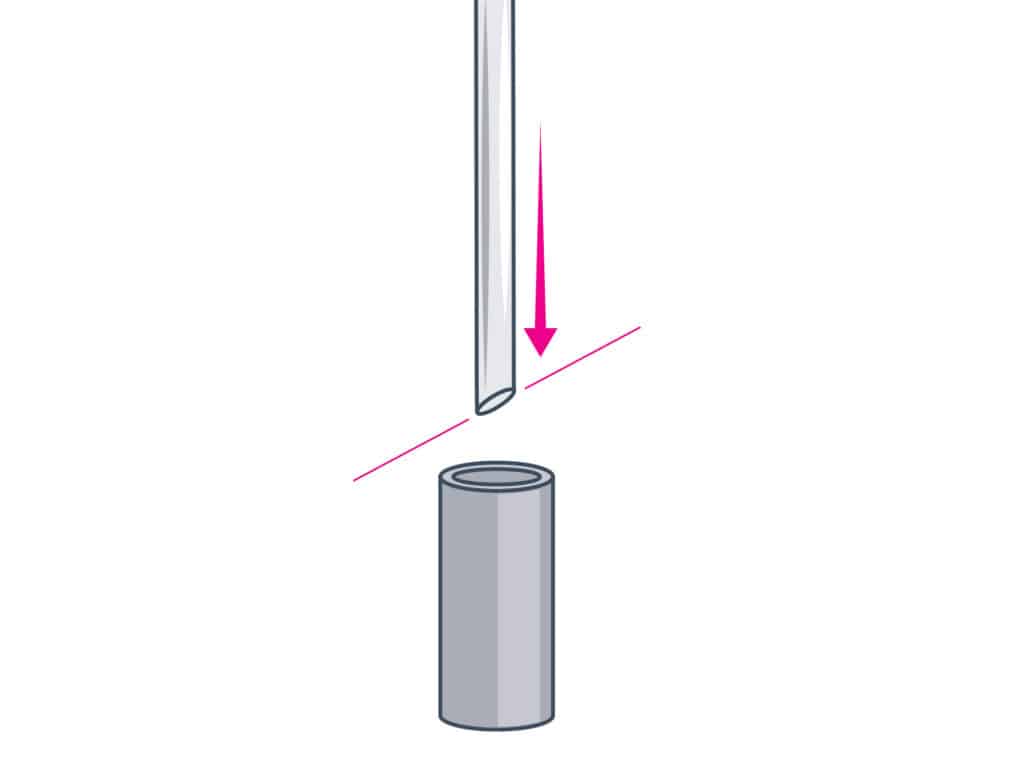

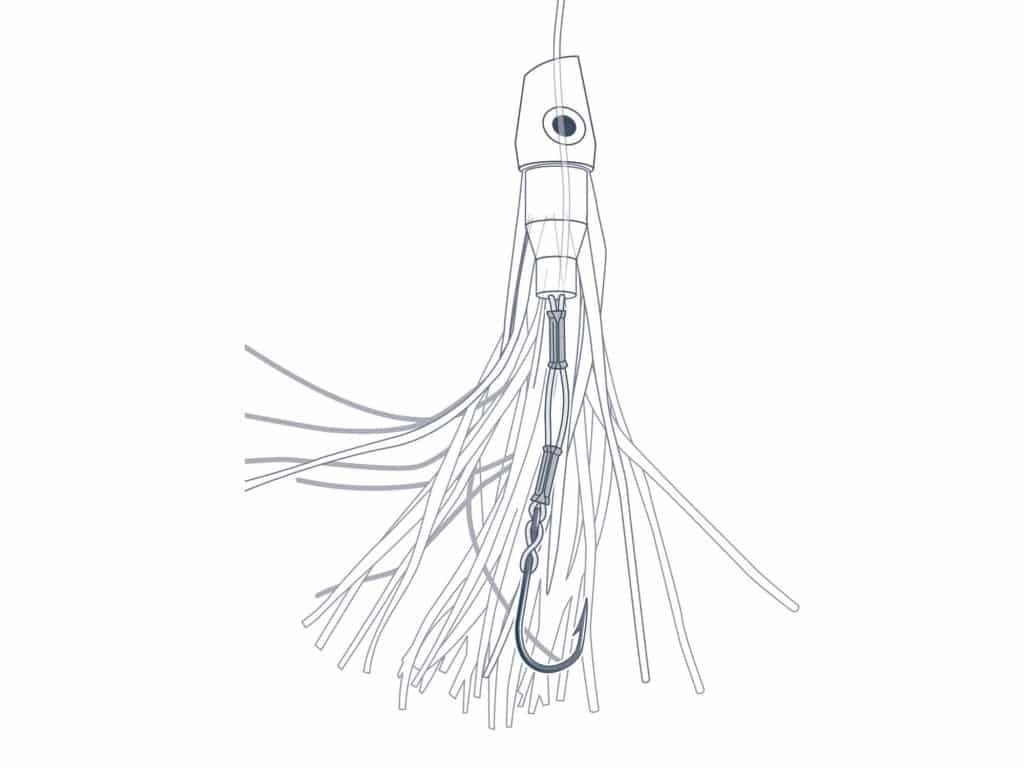

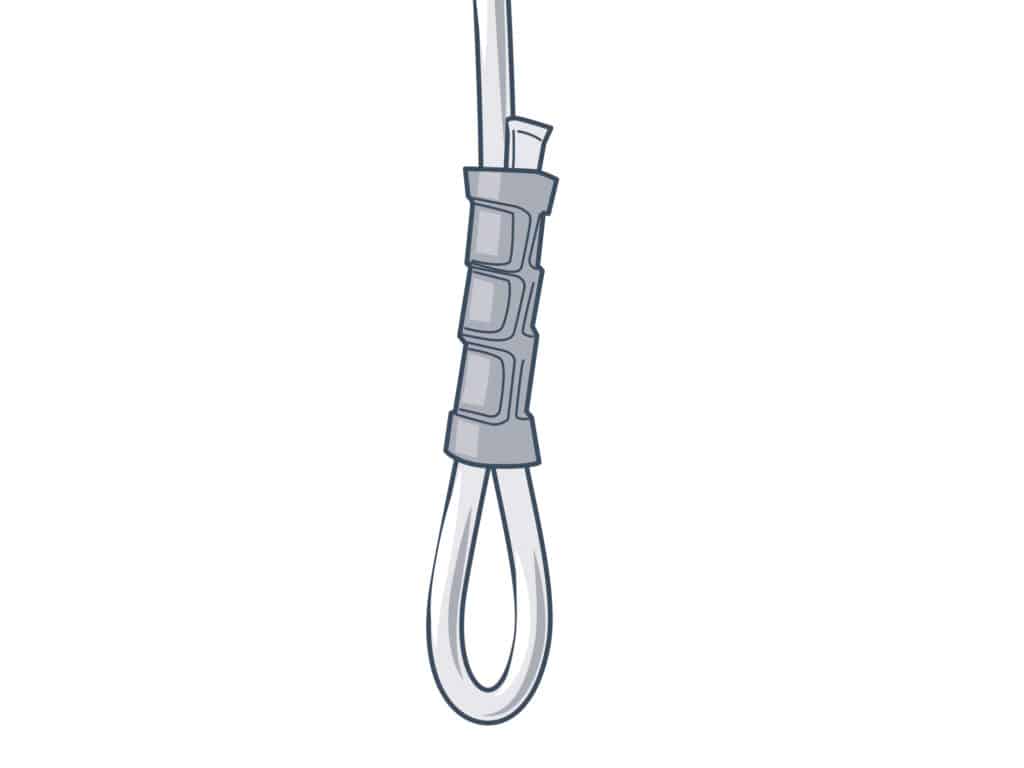

The objective of crimping, beyond forming loops and attaching hooks, is to compress a leader and meld it with the sleeve without damaging it. Read: zero slippage. Hence, it is critical to size the sleeve diameter to the leader.

Rick Mola, noted canyon angler and head of Fisherman’s World in Norwalk, Connecticut, says it’s impossible for sleeve manufacturers to offer a precise sleeve for mono or fluorocarbon leader in every specific pound-test due to their differing diameters. Therefore, sleeves are grouped into broader categories, such as 1.3-millimeter sleeves for 150- to 200-pound-test mono and 1.6-millimeter sleeves for 220- to 250-pound-test.

Mola recommends the smallest diameter sleeve through which the leader can pass, albeit tightly, versus a sleeve that is slightly larger and easier for the line to navigate. The latter has more slippage potential. When purchasing sleeves, Mola suggests bringing in your leader material (if not purchasing it at the same time), opening a pack of sleeves rated for that pound-test leader and actually fitting the leader into the sleeve. Sometimes a recommended sleeve size doesn’t fit precisely. It’s like trying on a pair of shoes before you buy.

“Sometimes the diameter of your leader falls between two sleeve sizes,” Mola says. “If your 200-pound mono has a diameter of 1.48 millimeters, a 1.3-millimeter sleeve will be too small for that line. You’ll have to move up to the next size; in this example, a 1.6-millimeter sleeve. Then the proper crimping procedure becomes even more important.”

TYPES OF SLEEVES

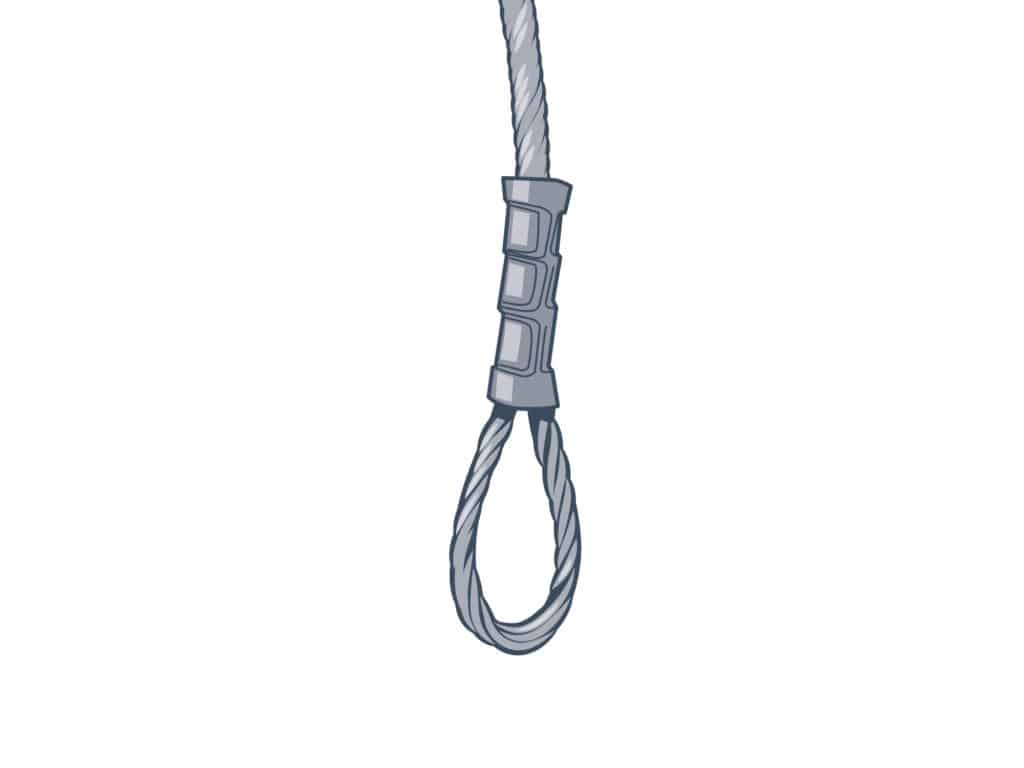

The best-selling saltwater sleeves are the oval, double-barrel designs. Round sleeves are less reliable on heavier leaders.

With a double-barrel sleeve, popular for monofilament and fluorocarbon leaders, each leader strand rests snugly within its own chamber. The chance of the leader laying over itself is eliminated (ditto with related damage). Scarring of the leader during the crimping process is also greatly reduced, providing it’s done correctly.

Double-barrel sleeves are also popular with cable rigs due to the exceptional bite the two metals generate. More on specific cable sleeves in a bit.

Oval sleeves are ideal for fluorocarbon leaders because fluorocarbon is more oval-shaped than round in diameter. Ovals often get the nod for heavier fluorocarbon as well as rounder nylon mono leaders used for big-game fishing (large marlin, swordfish, tunas and sharks), but they also serve well for lighter leaders for small game.

One caution with oval sleeves: Make certain the leader does not lay over itself prior to crimping.

MATERIAL THOUGHTS

According to Jack Butts from Rosco Terminal Tackle, there are only two metals used for crimps: aluminum and brass. “Nickel, zinc and black oxide are plated finishes applied to brass sleeves,” Butts explains. “These two metals are favored over stainless steel because they are softer and less likely to damage the leader. Brass and aluminum will not react with the salt water and, therefore, won’t pit or corrode.”

Big-game angler Jeffrey Liederman of Capt. Harry’s Fishing Supply opts for zinc-plated sleeves versus aluminum with cable leaders to prevent electrolysis from the two metals like a zinc anode does on an outboard. For mono and fluoro, both Liederman and Mola are proponents of aluminum because it shapes best to those materials and provides the snuggest fit.

CRIMPING GAMES

Oval and double-barrel crimping tools are designed with round dies for multiple sleeve sizes. Crimpers with a notch are designed for round sleeves. Mono up to 200-pound-test is easily crimped with a hand swage, whereas a bench swage is more precise for leaders over 200 pounds. Avoid crimping near a sleeve edge. The end of a properly crimped sleeve flares, whereas crimping at the edge crushes the metal into the leader, weakening it. Based on the length of the sleeve, more than one compression can be applied for extra insurance.

On cable, crimping the bitter end of a sleeve prevents slippage. Liederman compresses the tag end and flares the end facing the hook.

THE TEST

Mola won’t let any crimped system out of his store without a final test: a heavy-duty screw affixed to a desk. He simply attaches the connection to the screw and applies pressure. Any weakness reveals itself at this stage. Better here than when slugging it out with a heavyweight fish. After all, everyone enjoys a festive boat ride back in, especially when there’s a big fish laying in the cockpit or a release flag flying from one of the outriggers.