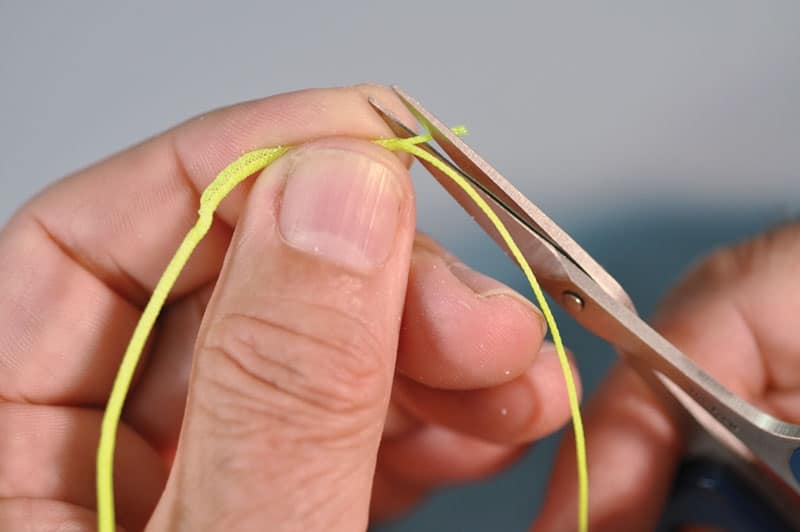

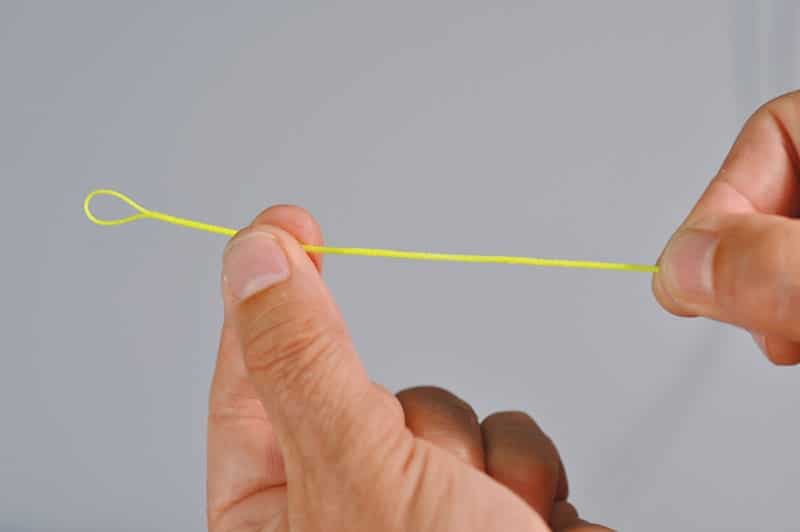

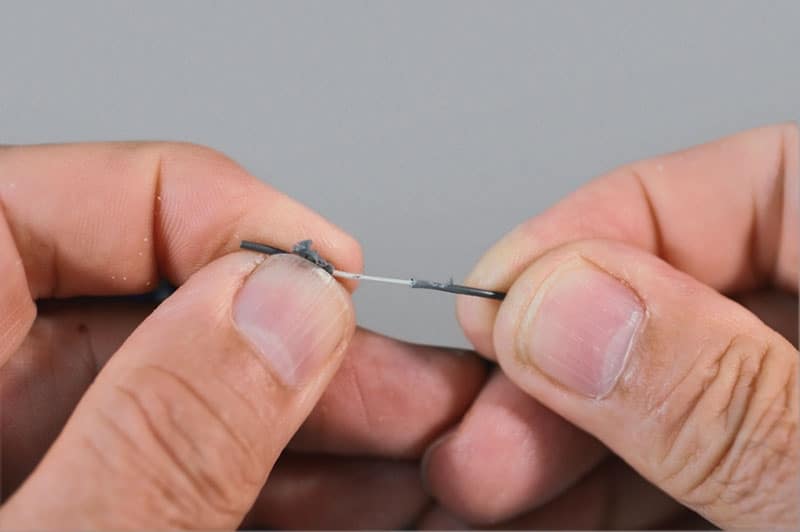

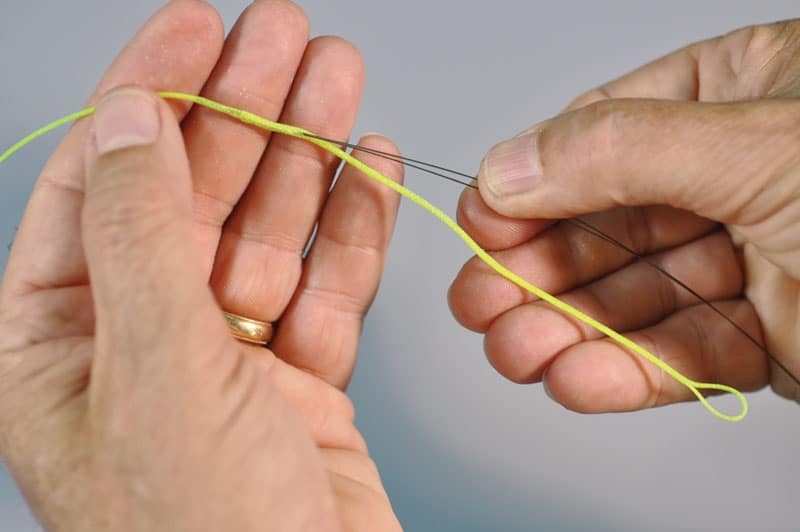

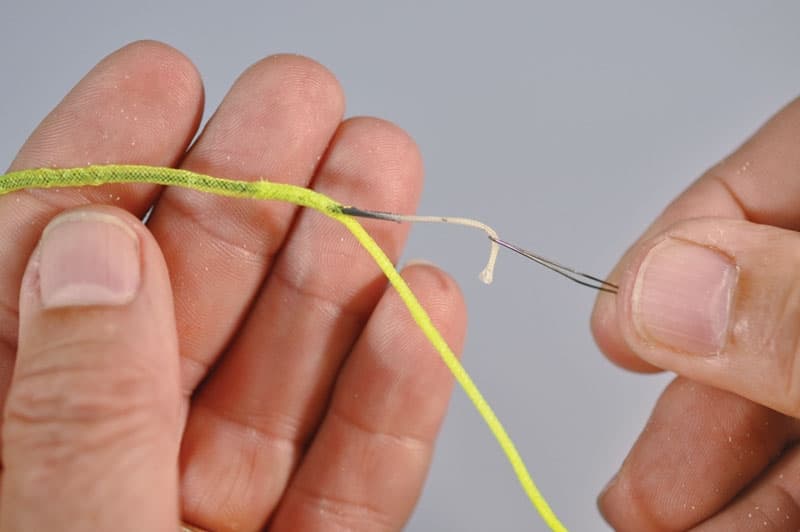

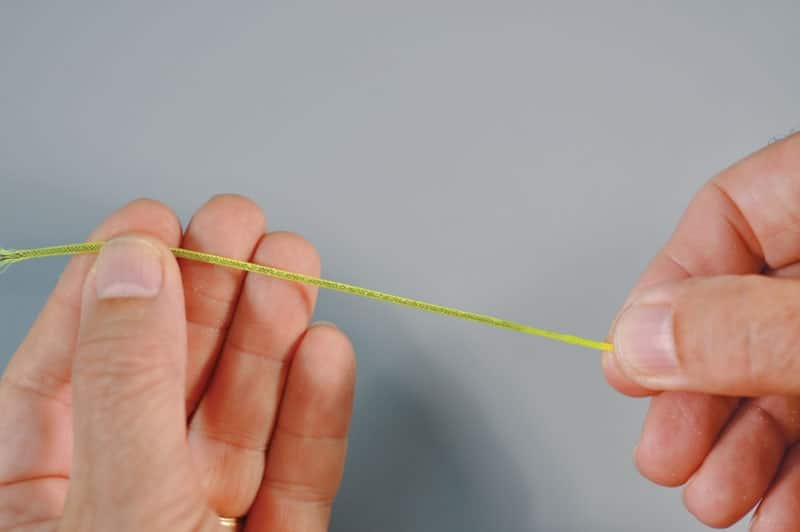

Braided Mono Loop Construction

Braided Mono Loop Construction

Braided Mono Loop Construction

Braided Mono Loop Construction

Braided Mono Loop Construction

Braided Mono Loop Construction

Braided Mono Loop Construction

Braided Mono Loop Construction

Braided Mono Loop Construction

Braided Mono Loop Construction

Braided Mono Loop Construction

Braided Mono Loop Construction