You probably don’t think much about the transducer for your fish finder until it malfunctions, and you consider the prospects of buying and installing a new one. But there are steps you can take to keep your current transducer performing at its peak and prolong its useful life. Here are seven tips for maintenance and fixing minor issues, gleaned from material provided by the leading manufacturer of marine transducers, Airmar Technology Corp. In some cases, you might need to haul the boat or put it on a trailer to perform these steps properly.

Face Cleaning

Use a soft cloth and mild household detergent such as Joy Liquid to keep the transducer face free of marine growth and petroleum residue. Avoid stiff- bristle brushes or high-pressure washer on the transducer. In cases of extreme marine growth, gently use a Scotch-Brite pad with mild household detergent, but be careful not to scratch the transducer face.

Face Painting

Transducer surfaces in constant contact with salt water must be coated with anti-fouling paint, according to Airmar. Use water-based anti-fouling paint only. Never use ketone-based paint, since ketones can attack many types of plastic and possibly damage the transducer.

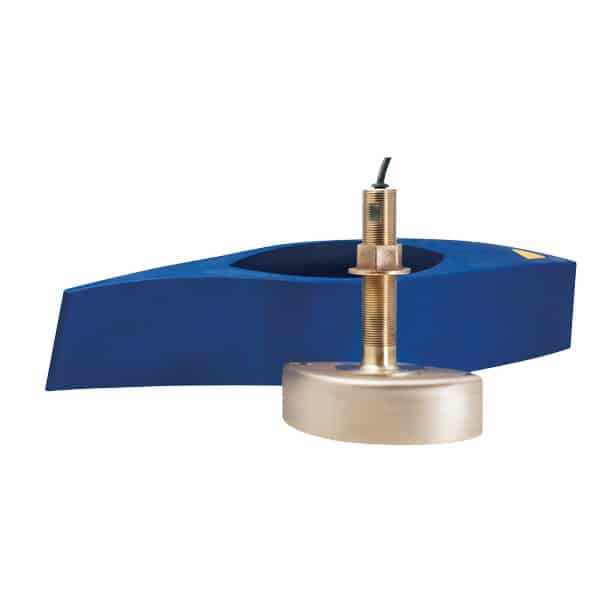

Avoid Dry Operation

If you have a multi-element chirp transducer, avoid turning on the fishfinder when the boat is out of the water. Without the cooling effect of water, these high-energy transducers can overheat, resulting in damage to the internal elements.

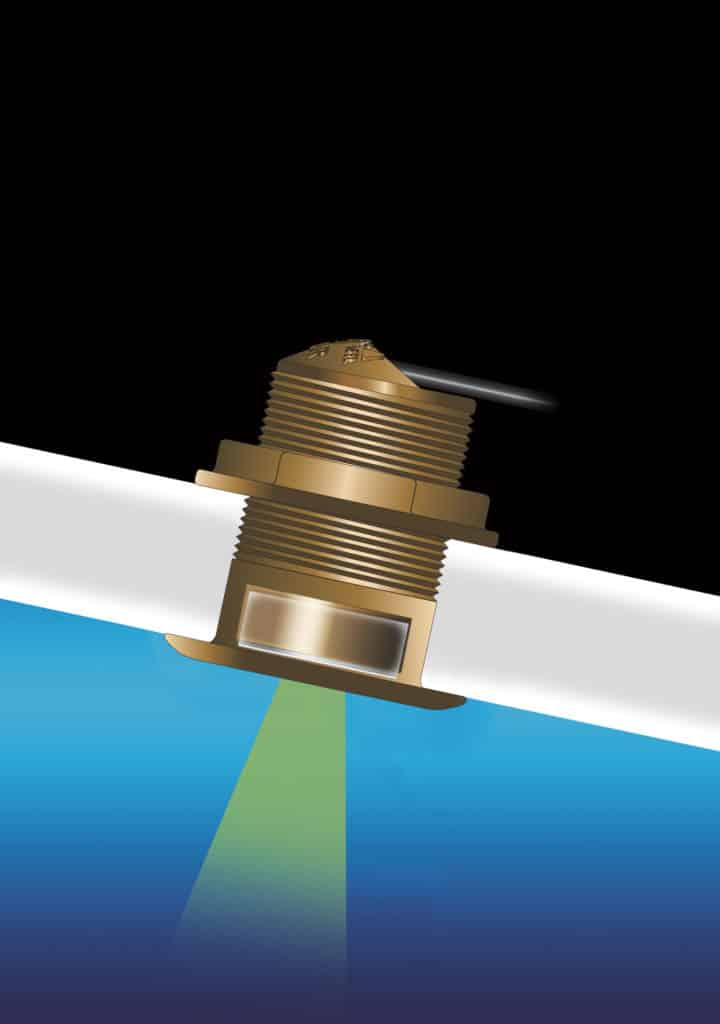

Check for Leaks

With through-hull transducers it is important to check for leaks in the bilge or other compartment where the transducer is installed. Do this right after a transducer is newly installed and every time you use the boat. With the boat in the water, check around the installation inside the hull. A small leak might not be readily apparent. Re-check about 2 to 3 hours later, but avoid leaving the boat unattended, especially if you suspect a leak. If there is a leak, haul the boat as soon as possible and have it fixed.

Inspect the Cable

Periodically inspect connections and connectors for signs of corrosion. Also, examine the cable for kinks, abrasions and cuts in the insulation.

Fix Damaged Cables

If the outer jacket/insulation of the cable in abraded or cut, make sure the internal wires are not damaged. If the internal conductors are OK, allow the cable to dry and fill in the damaged area with marine sealant, then cover the damaged area with electrical tape. If the wires inside are damaged, cut the cable and use Airmar’s splash-proof junction box (part no. 33-035) to splice the section. If you are good at soldering, you can also splice each pair of matching color conductors with rosin-core solder, wrap each splice with electrical tape, and fill the splice with marine sealant, then cover the area with heat-shrink tubing.

Test Your Transducer

A qualified marine electronics dealer/technician can test your current Airmar transducer using Airmar’s TDT1000 Tranducer Diagnostic Tester. This tester quickly determines if your transducer is in working condition via the SensorCheck app for IOS and Android mobile devices. The TDT1000 compares the tranducer performance to the factory specifications. This will tell you if you need to replace your transducer.