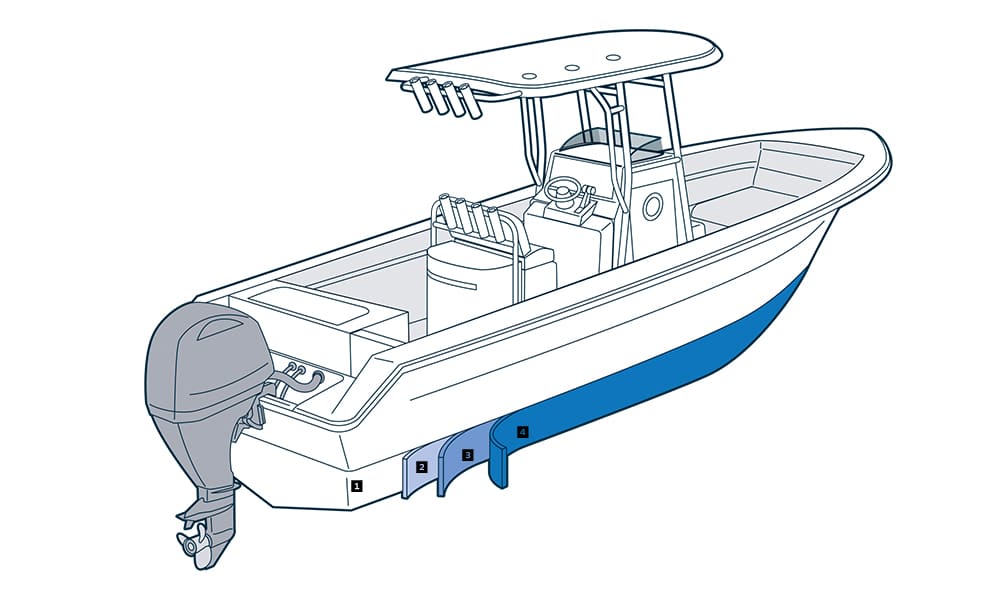

Achieving optimum performance from your boat depends on several factors, including hull design, horsepower, propellers, weight and wetted surface area.

Anything that adds more friction impacts speed, handling and fuel economy. That’s why keeping hulls that remain in the water for extended periods free of marine growth is so critical. The saltwater environment is an incubator for algae, slime and barnacles, and all negatively affect performance. Fortunately, the right bottom paint, properly applied, will significantly alleviate this problem.

“It’s important to match products to the environment. Bottom paints are formulated to meet different conditions and salinity levels,” says Tom Maellaro, a technical expert with Pettit Paint. “For example, a Florida or Southeast boater who doesn’t pull the boat annually needs a paint with a higher biocide content. With the right paint, they can probably get 18 to 24 months of service life from a paint job.”

Anti-fouling or bottom paint is made from four ingredients. The resin holds the coating film and controls the release of the biocide. Pigments provide the color and thickness, while solvents (or water) help with the application, flow and drying time. Biocides are the active compounds that repel fouling. Cuprous oxide, which contains copper, is the most common. Copper thiocyanate contains less copper content but produces brighter colors. Irgarol is an organic algaecide with a slow leach rate, and Econea is a metal-free biodegradable biocide. The Environmental Protection Agency regulates the use of biocides in the paint industry.

Biocides are designed to leach out over time so weed and animal growth won’t adhere to the submerged surface. Ablative anti-fouling formulas, the most common and typically with the highest copper content, require boat movement to work, like a bar of soap. As the paint and biocides wear off over time, new layers are exposed. Hard anti-fouling paints leach biocides while the paint mainly remains. Movement isn’t required, but this type needs to be reapplied after dry storage. Hybrid formulas are another type of hard paint best suited for trailerable and dry-rack stored boats. As the biocides leach away, the paint film breaks down to expose another layer.

“It’s cheap insurance to buy better bottom paint to match your environment,” Maellaro says. “The biggest expense is the prep and application. If you keep a boat in a slip year-round in high salinity and warm water that’s conducive to soft growth, pick a paint with a larger amount of Irgarol. If you want bright colors, go with copper thiocyanate. Eighty percent of painted hulls are black, 10 percent are blue, and everything else is other colors.”

Proper prep and applying multiple thin layers are the keys to longer-lasting paint jobs, Maellaro says. He recommends leaving spray application to the professionals. Do-it-yourself rollers can determine the square footage of the boat by multiplying the hull length by beam width by 0.85. Two coats of paint are normally recommended. Painting can take a few days, depending on weather, preparation and hull design. Stepped hulls or numerous lifting strakes may require hand-sanding, which increases man-hours.

Linda McDonald with Dog River Marina in Mobile, Alabama, says she’s seeing more customers choosing to bottom-paint themselves. The marina will haul the boat out and do the advance prep work.

“We start by pressure washing the hull in the wet slip area,” McDonald says. “That really removes a lot of the growth. We then soda-blast the entire bottom to scour it and remove any old, loose paint. We don’t sand at all anymore because of the environmental concerns. The soda blasting is very effective.” Costs run $45 per foot for larger craft, or $1,500 to $2,000 for smaller boats. Those fees do not include the haul-outs.

Read Next: Improve Your Boat’s Fuel Efficiency and Range

The next step in the process is the application of a barrier coat of primer, followed by two coats of the selected bottom paint.

Whether done professionally or by yourself, there’s a trend of adding a fishy wrinkle whenever the bottom is painted. Companies such as Sea Hawk Paints, FishRazr and Stencil Ease offer stencils or adhesive baitfish stickers to create optical illusions on hull bottoms. Single fish or schools of squid, flying fish, ballyhoo, mackerel and tuna are available. The jury is still out as far as effectiveness. But since the boat is a giant teaser and the bottom needs attention anyway, it can’t hurt, especially if a few more fish pop into the spread.